Adixen ASM142

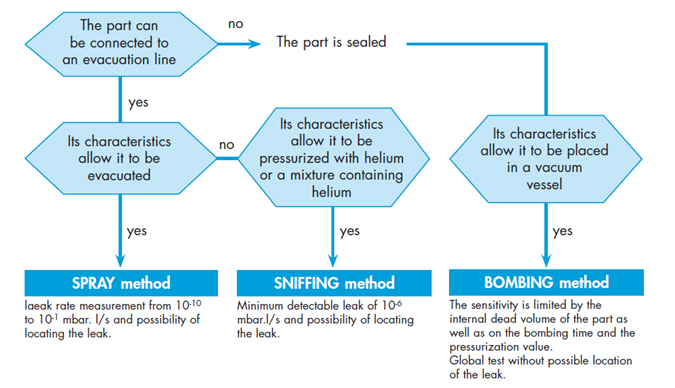

Leak detection is used to detect micro-openings, porosities, etc. in testparts. The detection of these cracks involves the use of a light tracer gas, which is capable of infiltrating the smallest leak quickly: Helium. The detector samples and measures the helium flow rate entering the test part via the leak(s). The testing method is selected according to the test part and the measurement accuracy required:

Spray Method

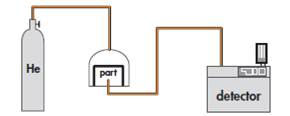

This involves removing air from the test part, connecting it to the analyzer and then spraying helium over the outer surface. The part is placed under a cover, into which helium is injected. The leak cannot be located. The detector measures the flow of helium penetrating the part.

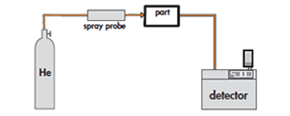

Potential leaking areas are sprayed with helium. The leak can be located. When spraying starts, the leak signal is not displayed instantaneously on the analyzer: there is a response time which depends on the volume V being tested and the helium pumping speed S of the system at the opening of the part, according to the following relation: T = V/S (T in seconds, V in litres, S in l/s) T is the time required for the signal to reach 63 % of the final value.

Sniffer Method

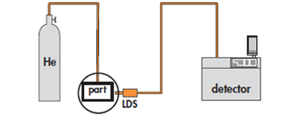

The test part is pressurized with helium. The detector, via an LDS (Long Distance Sniffer) probe, samples the helium escaping from the part. The part is placed under a cover containing a sniffer probe. The leak cannot be located. The helium from the leak accumulates over time inside the cover. The detector measures the concentration of helium.

The sniffer probe is moved over areas likely to contain leaks. The leak can be located. The signal supplied by the analyzer is not a direct measurement of the leak. The sniffer probe only samples part of the helium escaping from the part. The sample depends on the distance separating the leak from the tip of the probe.

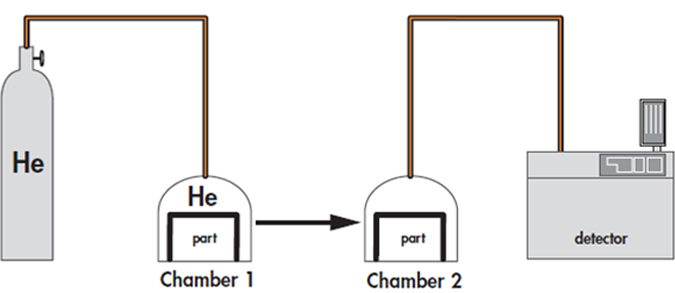

Bombing method

This method is used for sealed objects that cannot be connected directly to the detector (semiconductors, waterproof watches, etc.).

The part is placed in a chamber containing pressurized helium. The helium penetrates the part if it has a leak. The part is then removed from the chamber and placed in another vacuum chamber which is connected to the detector. The helium escapes from the part through the leak and produces a signal. This signal is not a direct measurement of the leak as the helium pressure inside the part is difficult to determine. Several parts play an important part such as: the pressurization time, the helium bombing pressure, the internal volume, the aeration time, the size of the leak.